Carrier 59TP6B Installation Manual: Article Plan (12/14/2025 00:42:09)

This manual details the 59TP6B furnace’s installation, start-up, operation, and maintenance. It covers multipoise flexibility, venting, and essential safety guidelines for technicians.

The 59TP6B is a two-stage, variable speed, ECM multipoise condensing gas furnace. It offers enhanced efficiency and comfort, requiring careful installation per these instructions.

Overview of the 59TP6B Model

The Carrier 59TP6B represents a significant advancement in home heating technology. This furnace is designed as a two-stage, variable speed model, utilizing an Electronically Commutated Motor (ECM) for optimized performance and energy savings. Its multipoise capability allows for versatile installation in attics, closets, or basements, adapting to various home configurations.

As a condensing gas furnace, the 59TP6B achieves high Annual Fuel Utilization Efficiency (AFUE) ratings, reducing heating costs and environmental impact. The unit’s construction prioritizes durability and reliability, ensuring long-lasting operation with proper maintenance. Understanding its features and adhering to these installation instructions are crucial for maximizing its benefits and ensuring safe, efficient performance. This model is available in nine different sizes.

Key Features and Benefits

The Carrier 59TP6B boasts several key features delivering substantial benefits to homeowners. Its two-stage operation provides consistent comfort while optimizing energy use, and the variable-speed ECM blower motor enhances airflow and reduces noise. The multipoise installation flexibility simplifies placement, accommodating diverse home layouts.

High AFUE ratings translate to lower energy bills and a reduced carbon footprint. Durable construction ensures long-term reliability, minimizing maintenance needs. This furnace offers enhanced indoor air quality through improved filtration capabilities. Proper installation, following these instructions, unlocks these benefits, providing years of efficient and comfortable heating.

Intended Use and Applications

The Carrier 59TP6B is designed for residential heating applications in adequately insulated and ventilated spaces. It’s intended for use with natural gas or propane, and is suitable for new installations or as a replacement for existing gas furnaces. This furnace excels in climates requiring consistent and reliable heating throughout the colder months.

Its multipoise capability makes it adaptable to various home configurations, including attics, basements, and closets. The 59TP6B is not intended for use in mobile homes or unconditioned spaces. Proper installation, adhering to these instructions, is crucial for safe and efficient operation within its intended applications.

Safety Precautions

Always prioritize safety during installation! Follow all electrical and gas guidelines, and heed warnings to prevent hazards and ensure proper furnace operation.

General Safety Warnings

Installation and service must be performed by qualified personnel. Disconnect all electrical power before servicing. Improper installation, adjustment, alteration, or service can cause injury or property damage. The furnace is permanently installed, requiring adherence to all provided instructions.

Carefully read and understand these instructions before beginning installation or service. Failure to follow these guidelines voids the warranty and may create unsafe operating conditions. Always follow local codes and regulations.

Be aware of potential hazards, including sharp edges and hot surfaces. Wear appropriate personal protective equipment (PPE) during installation and maintenance. Never operate the furnace without the proper venting system in place.

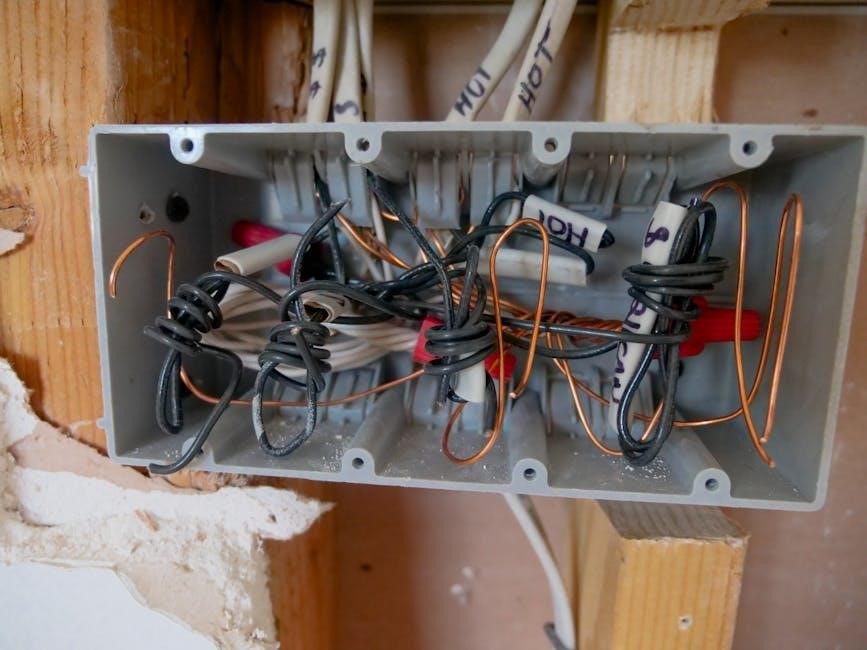

Electrical Safety Guidelines

Always disconnect electrical power at the breaker box before performing any electrical work. Verify power is off using a reliable testing device. All wiring must comply with local and national electrical codes. Ensure proper grounding of the unit to prevent electrical shock.

Use appropriately sized wiring and overcurrent protection devices as specified in the wiring diagrams. Double-check all connections for tightness and proper insulation.

Never work on electrical components with wet hands or in damp conditions. If any electrical components are damaged, replace them immediately with manufacturer-approved parts. Improper electrical connections can lead to fire hazards or equipment malfunction.

Gas Safety Requirements

Always follow the gas supplier’s instructions for connecting to the gas supply. Before starting, ensure the gas supply is turned off. Leak test all gas connections using a soap solution – never use a flame. Verify proper ventilation to prevent the accumulation of combustible gases.

Install a gas shut-off valve in an easily accessible location. Use only approved gas piping materials and fittings.

Regularly inspect gas lines for damage or leaks. If a gas leak is suspected, immediately shut off the gas supply and contact a qualified technician. Improper gas connections can result in explosions or carbon monoxide poisoning.

Unpacking and Inspection

Carefully inspect the shipment for damage upon arrival. Identify all components and parts against the packing list, reporting any discrepancies immediately to Carrier.

Receiving and Inspecting the Shipment

Upon delivery of the Carrier 59TP6B furnace, thoroughly inspect the entire shipment before signing any delivery receipts. Visually examine all packaging – the carton, pallets, and any protective wrapping – for signs of damage during transit, such as dents, punctures, or crushing. Document any external damage directly on the delivery receipt and request a detailed inspection report from the carrier.

Carefully open the packaging and compare the contents against the packing list included with the shipment. Verify that all listed components and parts are present and undamaged. Note any missing or damaged items on the delivery receipt and immediately contact your Carrier distributor or representative to report the issue. Retain all packaging materials until the inspection is complete and the claim is resolved.

Identifying Components and Parts

The Carrier 59TP6B furnace package includes several key components. These typically encompass the furnace cabinet, gas valve, blower assembly, inducer motor, heat exchanger, control board, and various wiring harnesses. Familiarize yourself with each part’s location and function before beginning installation. Refer to the detailed parts list included within the 93-page installation manual for specific identification numbers and diagrams.

Inspect each component for any shipping damage. Ensure all screws, bolts, and fasteners are present. The multipoise design requires specific accessories depending on the installation orientation; verify these are included. Proper identification prevents errors during assembly and ensures optimal performance of the two-stage variable speed ECM condensing gas furnace.

Reporting Damage or Missing Parts

Upon receiving the Carrier 59TP6B, thoroughly inspect the shipment for any visible damage. Note any dents, scratches, or crushed areas on the shipping container and the furnace itself. Immediately document all damage with photographs and detailed descriptions. Any discrepancies, such as missing components listed in the parts inventory, must be reported promptly.

Contact the Carrier distributor or the shipping carrier to file a claim. Retain all packaging materials until the claim is resolved. Accurate reporting ensures timely replacement of damaged or missing parts, preventing delays in the installation process. Refer to the installation instructions for contact information and claim procedures.

Installation Procedures

Proper installation requires adherence to these instructions, ensuring safe and efficient operation of the 59TP6B furnace. Flexibility and correct venting are key.

Multipose Installation Flexibility

The Carrier 59TP6B furnace boasts remarkable 4-way multipoise installation flexibility, significantly simplifying the installation process for HVAC professionals. This adaptability allows for vertical upflow, horizontal left, horizontal right, and downflow configurations, accommodating diverse home layouts and installation constraints. Technicians can optimize the furnace’s placement based on available space and existing ductwork, reducing the need for extensive modifications.

Careful consideration of unit clearances is crucial during multipoise installation to ensure proper airflow and prevent overheating. Refer to the detailed diagrams within these instructions for specific clearance requirements for each installation position. This feature enhances the furnace’s versatility and makes it suitable for a wide range of residential applications.

Unit Placement and Clearance Requirements

Proper unit placement is critical for safe and efficient operation of the 59TP6B furnace. Maintain specified clearances from combustible materials, ensuring adequate airflow for combustion and preventing potential fire hazards. These clearances vary depending on the installation position – upflow, downflow, or horizontal. Consult the detailed diagrams provided in these instructions for precise measurements.

Sufficient space must be allocated for servicing and future maintenance. Avoid obstructing access panels or components. Ensure the furnace is installed on a level surface, and that all ductwork connections are secure and properly sealed. Adhering to these requirements guarantees optimal performance and longevity of the unit.

Venting System Installation

Correct venting is paramount for safe operation of the 59TP6B furnace, ensuring proper exhaust of combustion gases. Always adhere to local codes and the manufacturer’s instructions regarding venting materials and configurations. The 59TP6B can be vented for various applications, including natural draft and forced-flue systems.

Utilize only approved venting materials, as specified in the ‘Approved Venting Materials’ section. Proper slope and support are crucial to prevent condensate buildup and ensure efficient draft. Carefully follow the venting system instructions to guarantee compliance and prevent carbon monoxide hazards. A correctly installed venting system is vital for safe and efficient furnace operation.

Approved Venting Materials

The Carrier 59TP6B furnace requires specific venting materials for safe and efficient operation. Approved materials include AL29-4C stainless steel vent pipe, and Category I gas venting systems. PVC, CPVC, or other plastic venting is strictly prohibited due to the furnace’s operating temperatures and potential for degradation.

Ensure all venting components are listed and labeled for use with gas appliances. Use appropriate connectors, supports, and sealing compounds designed for the chosen venting material. Refer to the detailed venting charts within the installation instructions for specific sizing and configuration requirements. Using non-approved materials voids the warranty and creates a safety hazard.

Venting System Instructions and Compliance

Proper venting is crucial for safe 59TP6B operation; strictly adhere to all local and national codes. The venting system must terminate outdoors, away from windows, doors, and air intakes. Ensure adequate clearance from surrounding structures and vegetation to prevent blockage. Follow the manufacturer’s instructions for proper slope and support of the vent piping.

Regularly inspect the venting system for corrosion, leaks, or obstructions. The referenced special venting system instructions must accompany the appliance. Compliance with these guidelines ensures optimal performance and prevents dangerous carbon monoxide buildup. Always consult the complete installation manual for detailed venting diagrams and specifications.

Gas and Electrical Connections

This section details safe gas piping installation, electrical wiring diagrams, and grounding requirements for the 59TP6B furnace, ensuring proper and compliant connections.

Gas Piping Installation

Proper gas piping installation is crucial for safe and efficient furnace operation. Always follow the gas supplier’s instructions and local codes meticulously. Ensure the gas supply pressure matches the furnace’s requirements, as specified on the unit’s rating plate. Use appropriately sized gas piping to prevent voltage drop and ensure adequate gas flow.

All gas connections must be leak-tested using a suitable leak detection solution. Before connecting the gas line, purge the piping to remove any debris or air. A manual shut-off valve should be installed upstream of the furnace for easy access and maintenance. Note: Enhanced installation reliability and operation are achieved by adhering to these guidelines;

Electrical Wiring Diagrams

Accurate electrical wiring is paramount for safe and reliable furnace functionality. Refer to the detailed wiring diagrams provided within the complete 59TP6B Installation, Start-Up, Operating and Service Manual (93 pages). These diagrams illustrate the correct connections for power supply, control wiring, and safety devices.

Ensure all wiring complies with local electrical codes and regulations. Use appropriately sized wiring for the specified voltage and amperage. Proper grounding is essential for safety and to prevent electrical interference. Note: Incorrect wiring can damage the furnace and create a hazardous situation; professional installation is recommended.

Grounding Requirements

Proper grounding is a critical safety measure during the 59TP6B furnace installation. It minimizes the risk of electrical shock and ensures the furnace operates reliably. The furnace chassis must be connected to a grounded electrical supply, adhering to all local and national electrical codes.

Utilize a dedicated grounding conductor of the appropriate gauge, as specified in the wiring diagrams. Verify the grounding connection’s integrity with a continuity test. Incorrect grounding can lead to dangerous electrical hazards and void the warranty. Always consult a qualified electrician if unsure about grounding procedures.

Start-Up and Testing

Before initial start-up, a thorough checklist is essential. Verify proper venting, gas connections, and electrical wiring for safe and efficient operation.

Pre-Start-Up Checklist

Prior to initiating the furnace, a comprehensive pre-start-up checklist is paramount for ensuring safe and optimal performance. First, meticulously verify all gas piping connections, employing leak detection solution to confirm a gas-tight seal. Next, inspect the electrical wiring, ensuring correct polarity and secure connections as per the wiring diagrams.

Confirm the venting system is correctly installed, adhering to approved materials and proper slope for condensate drainage. Double-check the combustion air provisions, guaranteeing adequate airflow for efficient combustion. Finally, inspect the furnace cabinet for any obstructions and ensure all access panels are securely fastened. Completing this checklist minimizes potential hazards and maximizes the longevity of the 59TP6B unit.

Initial Start-Up Procedure

Following the pre-start-up checklist, the initial start-up procedure requires careful execution. Begin by turning on the gas supply to the furnace and verifying the gas valve is in the ‘OFF’ position. Then, activate the electrical power supply to the unit. Set the thermostat to ‘HEAT’ mode and raise the temperature above the room temperature to initiate the heating cycle.

Observe the furnace through its complete heating cycle, monitoring for any unusual noises or error codes. Verify proper ignition and flame characteristics. Document all readings and observations for future reference. A successful start-up confirms correct installation and prepares the 59TP6B for efficient operation.

Combustion Air Requirements and Verification

Proper combustion air is crucial for safe and efficient 59TP6B operation. The furnace requires an adequate supply of fresh air for complete combustion, preventing carbon monoxide buildup. Verify the intake and exhaust vents are unobstructed and meet local codes. Confirm sufficient clearances around the furnace for airflow;

Utilize a combustion analyzer to measure flue gas composition, ensuring proper oxygen levels and minimal carbon monoxide. Document these readings. Address any deficiencies immediately, adjusting air supply or venting as needed. Regular verification safeguards against hazardous conditions and optimizes furnace performance.

Operation and Maintenance

This section outlines safe operating procedures and a routine maintenance schedule for the 59TP6B furnace, alongside troubleshooting guidance for common operational issues.

Operating Instructions

To operate the Carrier 59TP6B furnace, ensure the thermostat is set to ‘Heat’ and the desired temperature. The unit’s two-stage operation provides efficient heating, adjusting output based on demand. Familiarize yourself with the thermostat’s features for optimal control.

Regularly check air filters for cleanliness, replacing them as needed to maintain airflow and efficiency. Observe the furnace during operation for any unusual noises or smells, promptly addressing any concerns. The 59TP6B is designed for reliable, consistent performance when operated according to these guidelines. Always refer to the complete installation and service manual for detailed information and safety precautions. Proper operation extends the furnace’s lifespan and ensures homeowner comfort.

Routine Maintenance Schedule

To ensure optimal performance, a yearly professional inspection of the Carrier 59TP6B is recommended. This includes checking gas connections, combustion air, and venting systems for safety and efficiency.

Monthly, inspect and replace air filters as needed – a dirty filter restricts airflow. Biannually, visually inspect the burner assembly for cleanliness and proper operation. Regularly clean around the unit, removing debris. Following this schedule maximizes the furnace’s lifespan and maintains consistent heating. Refer to the full installation manual for detailed procedures and safety guidelines. Proactive maintenance prevents costly repairs and ensures homeowner comfort throughout the heating season.

Troubleshooting Common Issues

If the 59TP6B fails to start, verify the gas supply is on and the thermostat is properly set. A flashing error code on the control board indicates a specific problem – consult the installation manual’s troubleshooting section for interpretation.

For insufficient heating, check the air filter and ductwork for obstructions. Unusual noises may signal a blower motor issue or loose components. Always disconnect power before inspecting internal parts. If problems persist, contact a qualified HVAC technician. Attempting repairs without proper training can be dangerous and void the warranty. Prioritize safety and refer to the manual.